NASA has revealed how a mirror aboard its $1.5 billion Hubble Telescope became the wrong shape. Perkin-Elmer, which manufactured the Hubble telescope’s optics, completed the 2.4-meter primary mirror incorrectly because of errors in a test instrument, NASA said last week.

Hubble Problem detection of null corrector

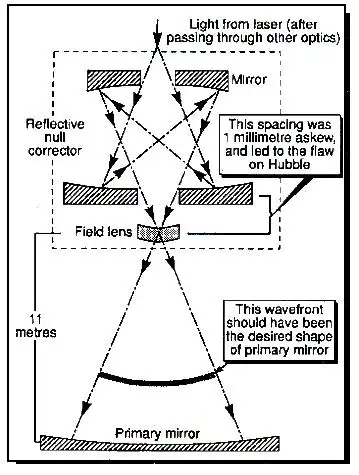

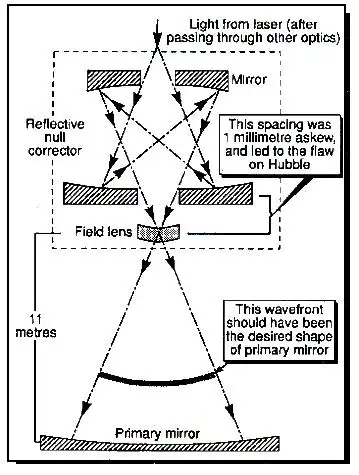

NASA found that a lens used in the test instrument, called the ‘reflective null corrector, is about a millimeter out of place. According to preliminary analysis, an error of this magnitude might be responsible for Hubble spherical aberration.

An astronomer at Beloit College in Wisconsin, and a codesigner of Hubble, Daniel Schroeder, says that the crucial error, the misalignment of a lens by a millimeter, is ‘huge’ by optical standards. Positions are measured in some optical instruments to lesser than a thousandth of a millimeter. A fraction of the wavelength of light.

Perkin-Elmer ignored the warnings despite being alerted to the problem by a cruder instrument. NASA says it trusted the refractive null corrector because the shape of the mirror had been ‘certified.’

The primary and secondary mirrors were tested separately at Perkin-Elmer’s Danbury plant in Connecticut, but the complete telescope was not tested before launch. NASA’s initial investigation cleared the design itself of blame, which led the agency to focus its inquiry on possible errors during the mirror-testing process.

Construction of Null corrector

Reflective null correctors are cylinders 76 centimeters high and about half a meter wide. The Hubble primary test kit consists of two mirrors and a lens. The instrument was supposed to have generated a wavefront matching the primary mirror’s shape by passing light between two mirrors and through a field lens.

Also See: Why Tesla is Not Considering LIDAR a Solution?

Due to errors in the corrector. The final mirror had the wrong shape since it was finished to match the wavefront.

Testing of Null corrector

Despite the primary’s polish and coating in 1981. The reflective null corrector remained unchanged at the Danbury plant, which Perkin-Elmer sold to Hughes Aircraft last year. Testing of the instrument is ongoing.

A committee investigating the error will now take steps to improve measurements and search for other errors. It was expected that the panel would meet in Danbury to overview testing procedures and data.

Interestingly, builders of large ground-based telescopes typically test mirrors two or three different ways and continue testing until the results agree. Moreover, Perkin-Elmer ignored tests with a smaller ‘refractive’ null corrector that used lenses rather than mirrors.

Refractive instruments were deemed ‘much cruder’ than reflective null correctors. They weren’t ‘certified’ to measure spherical aberrations nor intended to yield precise surface roughness measurements. Apparently, the cruder instrument yielded the correct result.

Also See: James Webb Telescope to understand space in early Universe

Ford Aerospace

In geosynchronous orbit, the GOES satellites record images and collect temperature and moisture profiles in the atmosphere. The new satellites, designed by Ford Aerospace, rely on a pair of moving flat mirrors to reflect light from Earth into telescopes on board.

This problem arises from the flat mirrors, which are 30 by 50 centimeters.

When sunlight shines on some parts of the mirrors. It doesn’t heat them uniformly, causing their surfaces to become less flat than they should be. Early tests of the instruments revealed odd data, and NASA traced the problem to differential heating of the mirrors.